What’s New at Root Neal

HOW DO SCALES WORK?

Scales are used in almost every facet of life, but how do they actually work? No matter their function, all scales work basically the same way.

A Whole New Dimension to Outbound Shipping

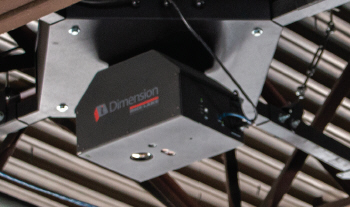

INTEGRATING DIMENSIONAL WEIGHT SHIPPING AT MIDWEST MOTOR EXPRESS WITH IDIMENSION® SERIES DIMENSIONERS

Midwest Motor Express, Inc. has seen exponential growth in the 100 years since its 1918 opening as Snyder’s Dray and Transfer in Bismark, North Dakota. The company began with humble beginnings, hauling sand, gravel and freight with horses and wagons. Today, Midwest Motor Express is one of the pre-eminent regional carriers in the upper Midwest and greater Northwest.

Although an attribution to their success, Midwest Motor Express’ thriving growth comes with operational challenges, including adapting to industry standards on such a large scale. Midwest Motor Express operates 34 terminals across 14 states, and when new industry regulations and standard operating best practices are enacted, Midwest Motor Express needs to ensure uniformity across all of their facilities.

A five-minute manual measurement process has been shortened to three seconds thanks to iDimension 400.

When dimensional weight (DIM weight) shipping became more heavily enacted in the early 2010s, Midwest Motor Express saw the potential as a shipping carrier to adopt DIM weight billing. Midwest Motor Express also knew in order to make the change from standard weight to DIM weight billing, they needed a solution that was dependable, accurate and easy to integrate into their large-scale operation.

A five-minute manual measurement process has been shortened to three seconds thanks to iDimension 400.

Dimensional weight shipping is the shipping and logistics industry’s solution for maximizing a carrier’s ability to load less than truckload (LTL) freight more efficiently. With the e-commerce market booming at the turn of the 21st century, carriers saw an ever-growing increase in ground LTL shipments. These e-commerce packages were being shipped in ways that created excess void and packaging material space. Carriers like Midwest Motor Express saw a growing trend of truckloads under capacity by weight, even though volume per truckload was at capacity. They were shipping lighter truckloads than ever before, which had a negative impact on their bottom line.

With each truckload that reached space capacity before weight capacity, carriers needed to dispatch more loads from transfer stations and the original shippers were not charged for the extra space their packages created.

When a carrier can utilize more space, they fulfill more shipments at a faster, leaner and heightened yield. The best way to utilize more space in packaging is to decrease the amount of void or packing material space by implementing right-size packaging and using high-efficacy materials for product cushioning.

To encourage shippers to pack goods more efficiently, carriers began using dimensional weight shipping costs, which is a billing method that uses the volume of the package (length x weight x height) and an industry standard divisor (currently 139 for domestic shipments and 169 for international) to calculate the package’s DIM weight in pounds. The carrier then compares the DIM weight to the package’s standard weight and bills whichever is greater.

The DIM weight movement provided the answer for carriers to maintain profitability and be more efficient with their shipping processes. However, change comes with its own set of obstacles. To begin implementing DIM weight billing practices, carriers need to capture, document and charge shippers based on the package’s dimensional weight.

For Midwest Motor Express, that meant changing their entire freight processing and billing procedures.

To ensure the DIM weight movement wasn’t just a passing fad, Midwest Motor Express bid their time to truly test the dimensional weight market and usability by allowing nationwide carriers to spearhead the undertaking.

The traditional method of manually measuring packages to calculate and determine DIM weight, actual weight and billable weight for each package is labor and time intensive. To combat this increased process time and labor, large carriers began installing and integrating dimensioning systems into their standard work operations—committing to the DIM weight movement.

By allowing national carriers to set the industry standard for DIM weight, Midwest Motor Express was also able to spend time and ensure due diligence in choosing a technology provider to supply their dimensioning system and actual weight needs. When Midwest Motor Express decided to purchase an iDimension Series dimensioning system from Rice Lake Weighing Systems, they were confident DIM weight shipping was the best move for their company. The industry was making a rapid progression into DIM weight, as was the competitive market for carriers to adopt DIM weight practices. Almost immediately after the installation and integration of a Rice Lake iDimension 400 dimensioning system, Midwest Motor Express saw its benefits.

“It has been our saving grace,” says Michael Brennan, Director of Midwest Motor Express when asked how integrating an iDimension Series has impacted business. “I truly believe the future for Midwest Motor Express and the industry is going to be dimensional pricing and capturing data,” continues Brennan. The iDimension 400 at one of Midwest Motor Express’ largest outbound terminals in Mounds View, Minnesota is one of the first dimensioning systems installed at Midwest Motor Express.

Shipping process efficiency was increased with Rice Lake forklift scales, instrumentation and dimensioners.

The iDimension 400 captures Legal for Trade, NTEP Certified dimensions at 8 × 8 × 8 feet with 0.5 inches of accuracy. It is capable of dimensioning up to 300 pallets per hour (which is faster than most operations can keep up with) and captures dimensions with 360-degree access for easy pallet placement in the center of the target zone. The iDimension 400 at Midwest Motor Express takes only three seconds to do what a field inspector would do manually in as much as five minutes. With many terminals in their region, Midwest Motor Express plans to integrate an iDimension 400 in each of their nine large outbound terminals.

Ease of integration and dependability were driving factors in Midwest Motor Express’ search for a dimensioning system supplier. Midwest Motor Express knew that an iDimension dimensioner would provide all of the information they needed with dependability. What they didn’t expect was Rice Lake Weighing Systems’ dedication and exceptional hands-on customer service to ensure the dimensioning system was adding value to their operation. “It’s been a great partnership to work with Rice Lake,” says Brennan. Midwest Motor Express utilizes Rice Lake products throughout their terminal, including floor scales, forklift scales and instrumentation.

“Rice Lake is all we could have asked for in a company to work with,” continues Brennan. Dependability in service and utmost customer service are qualities both Midwest Motor Express and Rice Lake Weighing Systems share, creating an unmatched partnership in logistics.

Midwest Motor Express is home to many claims of fame, including their experienced drivers, impeccable safety record and one of the lowest claim ratios in the business. The company continues to grow, and with weighing and dimensioning systems integrated into their proven business model, a future of continued superior transportation services as an industry leader is en route for Midwest Motor Express.